This website was created to introduce the various aspects considered in the MEng Thesis of Gareth Dennis and will continue to be updated as part of the project.

Photo credits: © 2013 Gareth Dennisunless otherwise stated

A rail can be deemed to have failed if it does not meet either its serviceability or its ultimate limit states.

The consequences of rail failure can range from minor vehicle damage and wheel-derailments to catastrophic whole-vehicle derailments leading to loss of life. A number of safety reports into such incidents have been included in the Existing Research section of the website.

Both conditions will be considered as part of this project.

A rail will fail its serviceability limit state if it is no longer capable of keeping a rail vehicle’s wheelsets aligned with the direction of the track, or if the likelihood of flange-climb derailment becomes significant.

It is usual for a worn rail to reach this state before failing under its ultimate limit state.

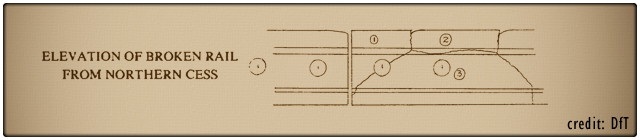

The ultimate limit state for steel rails is the structural failure of the rail through shear fracture or in bending. For this to occur, the cross sectional profile must have been sufficiently impacted by wear either so that fractures propagate and result in a brittle failure or that the plastic properties of the rail result in its failure when subjected to loading.

Though failure of this type is usually rare, a combination of rail wear and inherent fractures in the rail material can be more common.

This section of the website will be further expanded as the literature review continues, and as any physical testing is undertaken.