This website was created to introduce the various aspects considered in the MEng Thesis of Gareth Dennis and will continue to be updated as part of the project.

Photo credits: © 2013 Gareth Dennisunless otherwise stated

This project intends to summarise common wear mechanisms and will attempt to outline best practice regarding the measurement of rail wear.

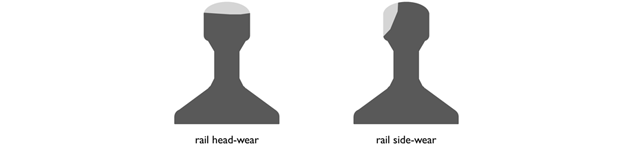

The two primary mechanisms for wear in steel running rails (Shu et al., 2005) are side-wear and height-loss at the head of the rail profile (as shown below).

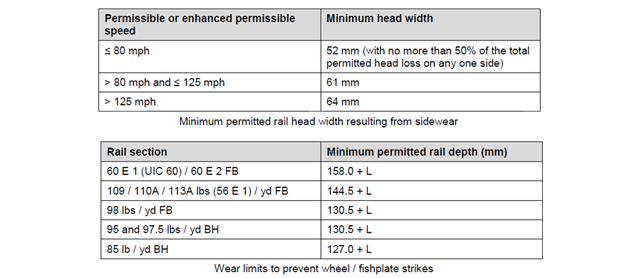

The limits that have been defined by the British Rail Group Standards (RSSB, 2011) for each type of wear are detailed in the tables below. The top table defines maximum rail side-wear for certain designations of railway usage. The bottom table details the maximum rail head height-loss allowed for various rail sections.

These values are predominantly for use on the mainline network, and their relevance will be established as part of this project.

Rail wear is influenced by a number of factors (Gordon et al., 2009). These include the range of temperatures that the rail is exposed to; loading frequency and magnitude; rail cant; rail position with respect to curves, switches and crossings; type of vehicles running on the line; running speed and so on.

Problems can occur as a result of rail wear that are short of rail failure. When a rail is sufficiently worn it can result in excessive vibrations in the wheelsets of vehicles running over it, and in certain conditions wheels themselves can be dangerously worn by

The simplest methods for measuring rail wear involve using templates with an unworn rail profile to compare to points along the running rail.

On the mainline wear measurements are often made using laser sights and for more complicated fracturing, ultrasonic testing or other imaging methods can be utilised. These methods are most often beyond the means of heritage railway lines.

The usual manner in which wear is treated on the mainline network is by grinding (RAIB, 2012), which corrects the profile of the rail head and reduces wheel vibration and damage. When the wear exceeds the limits detailed by the standards, it can be replaced by a newer rail and used in a location where lower tolerances are required.